Component Introduction

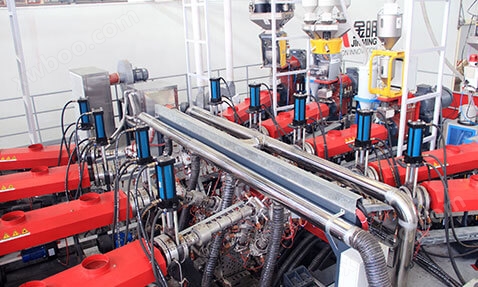

Extrusion Machine

Based on more than 30 years of experience in extrusion system design at Jinming, a low-temperature extrusion system suitable for processing various materials has been developed through flow rate testing and screw rheological simulation of processing performance parameters of various raw materials. This system can effectively reduce material extrusion temperature and shear, improve film physical properties, and help reduce unit energy consumption.

Distributor and mold head

The distributor and automatic flat die system adopt a floating layered plug design, which can be adjusted according to the extrusion volume. Three dimensional melt pipeline, reducing length and avoiding dead corners. Design a single material edge wrapping system to effectively reduce the cutting loss of expensive materials. By optimizing the processing parameters, the technical problem of PA, EVOH and other materials being wrapped by other layers has been effectively solved.

control system

Equipped with Siemens computer centralized control system, the extrusion part, extrusion temperature control part, transmission control part, winding control part, edge material collection control part, and roller temperature control part can be automatically controlled through the central control unit PLC. The temperature control unit adopts imported high-precision temperature control modules from Germany. The main menu screen is set on the touch screen, and the operator can easily perform menu operations to set, modify, and query parameters of the monitored object.